2004 Jeep TJ Wrangler Rubicon

up next

- fuel pump, long crank when cold, loss of pressure when off

- replace clutch

- new soft top

- regear to 4.88

- ball joints

- front brakes

- flush brake fluid

- aftermarket swaybar - swayloc or antirock

- fuel injectors or just o- ings?

- rms

- electrical cables

- service UCA johnny joints

- service front track bar

Todo List

- tire rotation at 147,000

- oil change at 144,086mi

- 35s

- paint BL gap

- skid nutsert replacement

- surface rust in drivers footwell

- steering pillow

- control arm mini-skids

- sliders

- hood dent repair?

- rear bumper

- half doors

- paint axles?

- Tailgate Dome Light Activation Switch

- A/C Defeat

- rain cover

- currie currect lync

- 241 rear seal

- raise gas skid

- morryde tailgate hinges

- chromoly axle shafts

- paint front frame suspension mounts

- fix blend door

- rear axle seals

- front axle seals

- steering skid

- dead pedal

- arb air lockers

- on board air

- tailgate table

- new exhaust

- trailer?

- fox shocks

done

- 133,300mi | 2021-09-30

- spark plugs | 2021-09-31 @ 133,308mi

- seat risers | 2021-10-01 @ 133,322mi

- 133,333mi | 2021-10-2

- oil change | 2021-10-04

- coolant flush | 2021-10-17 @ 133,500mi

- valve cover gasket | 2021-10-18 @ 133,516mi

- door hinge bushings | 2021-10-21

- h4 headlight conversion | 2021-10-25

- install factory front bumper | 2021-11-03

- relocate factory locker pumps | 2021-11-03

- install polk 5.25" front speakers | 2021-11-03

- repair fog light switch | 2021-11-03

- tcase fluid | 2021-11-12 @ 133,650mi

- transmission fluid | 2021-11-12 @ 133,650mi

- installed kc fog lights | 2021-11-14

- replaced lug nuts with gorilla | 2021-11-16

- rear diff fluid | 2021-11-22 @ 133,760mi

- replaced rear diff side air fitting | 2021-11-23

- 134,000mi | 2021-12-17

- intstall savvy adjustable control arms | 2021-11-30

- install track bars, jks springs, rancho shocks | 2021-12-30

- tom woods rear driveshaft | 2021-12-30

- alignment | 2021-12-30

- diy quick disconnects | 2022-01-13

- claytone reverse led lights | 2022-01-15

- replaced transmission backup sensor | 2022-01-15

- tires cooper evolution 285/75r16 | 2022-02-09

- savvy body lift | 2022-02-22

- ucf extra clearance skid | 2022-02-22

- jks mml | 2022-02-22

- rear tow point | 2022-03-20

- center axle under jeep | 2022-03-10

- set bumpstops | 2022-03-12

- 135,000mi | 2022-04-12

- new sub install | 2022-05-06

- passed state inspection | 2022-08-25 @ 135,915mi

- grease front end | 2022-08-30

- axle ujoints | 2022-09-05 @ 135,972mi

- unit bearings/hubs | 2022-09-05 @ 135,972mi

- adjust steering stops | 2022-09-05 @ 135,972mi

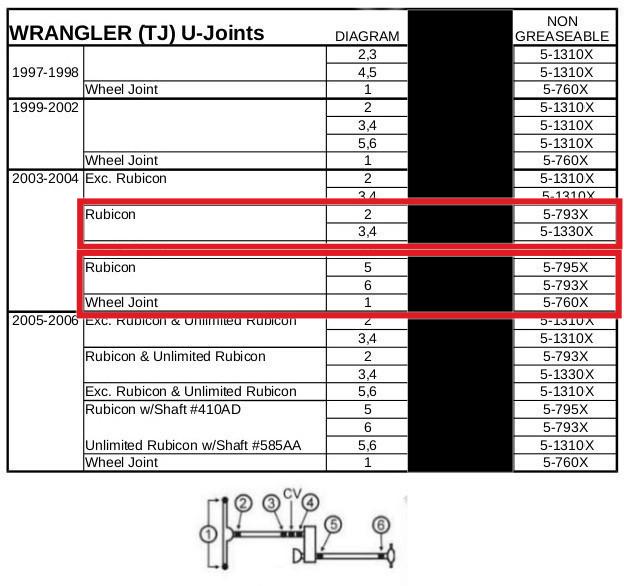

- rebuild front driveshaft | 2022-09-06 @ 136,002mi

- 136,000mi | 2022-09-06

- frame drain holes | 2022-09-08 @ 136,038mi

- seat bushings| 2022-09-10 @ 136,056mi

- locker switches wiring | 2022-09-12 @ 136,072mi

- new starter | 2022-09-17 @ 136,125mi

- drill rear crossmember drain hole | 2022-09-18 @ 136,138mi

- clean IAC | 2022-09-21

- clearanced gas skid for rear track bar | 2022-09-26 | 051

- zj steering | 2022-09-30 @ 136,292mi | 053

- service front diff w/ lubelocker | 2022-09-30 @ 136,292mi | 053

- alignment fr: 58 1/8 rr: 58 1/4 | 2022-09-30 @ 136,292mi

- installed currie shock mount extensions | 2022-10-01 @ 136,325mi

- air filter Wix 46081 | 2022-10-07 @ 136,392mi | 055

- service LCA johnny joints | 2022-10-08 @ 136,400mi | 054

- install rear black max shocks | 2022-10-08 @ 136,400mi | 055

- install trunk | 2022-10-08 | 055

- service front UCA johnny joints | 2022-10-15 @136,500mi

- replaced windshield wipers (bosch microedge 40713) | 2022-11-12 | 055

- 137,000mi | 2023-01-16

- front component speakers | 2023-02-13 | 056

- oil pan and gasket | 2023-02-25 | 057

- oil change | 2023-02-25 @137,175mi

- fix exhaust | 2023-02-27 @137,175mi | 058

- new radio head unit | 2023-03-07 | 059

- radio separate amp | 2023-03-10 | 059

- installed Zone offroad sway disconnects | 2023-04-24 @ 137,895mi | 063

- service rear UCA johnny joints | 2023-04-29 @137,925mi | 063

- replaced leaking passenger rear black max shock | 2023-04-29 @137,925mi | 063

- 138,000mi | 2023-05-07

- rotate tires | 2023-06-07 @ 138,182mi

- winch plate | 2023-06-28 | 071

- 139,000mi | 2023-09-15

- oil change | 2023-09-22 @139,086mi

- blackstone lab report | 2023-10-18 @ 139,086mi | 076

- rear lower CA johnny joint service | 2023-10-07 @ 139,282mi

- replace cooling system | 2023-10-09 @ 139,282mi | 073

- replace timing chain | 2023-10-09 @ 139,282mi | 073

- install winch rope | 2023-10-10 @ 139,308mi | 074

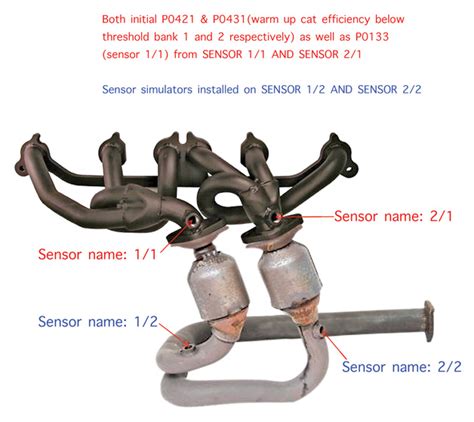

- O2 sensors | 2023-10-11 @ 139,321mi | 074

- Hella H4 100/80w bulbs | 2023-10-11 | 074

- passed state inspection | 2023-10-17 @ 139,741mi

- cruise control installed | 2023-10-26 @ 139,850mi | 077

- new AGM battery | 2023-11-02 @ 139,961mi | 077

- 140,000mi | 2023-11-06

- rotate tires | 2024-02-26 @ 140,818

- 141,000mi | 2024-04-05

- replaced hood footman loop Crown 55176422K | 2024-06-03 | 077

- soft top tension straps | 2024-06-15 | 077

- Kicker Sub install | 2024-06-15 | 077

- service front LCA johnny joints | 2024-06-17 @ 141,513mi

- service rear LCA johnny joints | 2024-06-19 @ 141,513mi

- replace fan clutch usmw 25516 | 2024-06-28 @ 141,710mi

- doors off mirrors | 2024-07-12

- Steering Wheel | 2024-08-17 | 079

- 142,000mi | 2024-08-25

- replace seat foam | 2024-09-21

- install seat heaters | 2024-09-21

- rotate tires | 2024-11-29 @ 142,870mi

- 143,000mi | 2024-12-19

- speedo correction | 2025-03-22 Set @ -4.1%

- AC compressor clutch replacement | 2025-05-14 @ 143,812mi

- 144,000mi | 2025-06-14

- Replacement center HVAC vents | 2025-06-25

- service front LCA johnny joints | 2025-07-26 @ 144911

- service front UCA johnny joints | 2025-07-29 @ 144916

- 145,000mi | 2025-07-30

reference

- defrost only fix

- fuse and relay

- cooling system

- rubicon factory lockers

- shocks

- service johnny joints

- pinion angle

- torque specs

- regear

- m8000

- rough start

- viair 88p

- WTJF How To Index

- JJ nut tool

O2 Sensors

NTK was the oem supplier

WTJF: The Official Jeep Wrangler TJ Oxygen (O2) Sensor Thread

2004 6 cyl

- NGK #23137 - Bank 1, Sensor 1 (Upstream) Rockauto

- NGK #23135 - Bank 2, Sensor 1 (Upstream) Rockauto

- NGK #23132 - Bank 1, Sensor 2 (Downstream) Rockauto

- NGK #23531 - Bank 2, Sensor 2 (Downstream) Rockauto

O2 Sensor Socket Amazon

O2 sensor wiring extensions amazon

Bank 1 sensor 1 =Red

Bank 1 Sensor 2 =Blue

Bank 2 Sensor 1 =Yellow

Bank 2 Sensor 2 =Green

https://wranglertjforum.com/threads/daily-driver-go-where-i-want-to-build.9410/post-1609948 Fuel trim strategy with narrow band sensors is for the PCM to constantly oscillate between rich and lean, so the sensors make wide swings from just above 0V to about 1V constantly. This is for the upstream sensors. The downstream sensors aren’t used in fuel trim strategy - only for emissions checks (making sure the cats are working).

axle ujoints

spicer 5-760x

Article: Axle U-Joints & unit bearings

WTJF: Jeep Wrangler TJ U-Joint Replacement

WTJF: Replacing U-Joints: Do You Prefer a Hammer or a Press?

Jeep Wrangler TJ Front Axle U-Joint Replacement Youtube

5-760x pair Amazon

Amazon: spicer 5-760x

How To Remove The Front Axle and Change The U joint On YJ/TJ/XJ Jeep Wrangler - YouTube

WTJF: How to Install a Jeep Wrangler Front Axle U-Joint and Hub

WTJF: ElectricWizards 2000 TJ Sport Build

mr blaine: Axle u joint replacement | WTJF

Mr Blaine:

- never use a press on axle ujoints

- The hammer and socket method wont damage the yoke.

- No need to protect the cap being driven in, it is much harder than any hammer so don’t be afraid to beat on it.

- When you drive the first cap in, take it below flush so the other pin is sticking out a bit further. That way you can pull the cross halfway out of the installed cap and it sticks up high enough on the other side to get the second cap started and engage the needle bearings in both caps. That prevents a needle from falling over and getting trapped which is always a mess. That is also when you install the clip in the first cap’s groove so when you hammer in the second cap, it pushes the first one back against the snap ring.

- When that is done, the second groove will be showing and when you install the snap ring, it will be loose. You need to set the caps back against the snap rings so the pressure of the cap pushes them against the inside of the yoke. That is done by holding the assembled axle pointing straight away from you in one hand and then taking a nice size hammer and smacking the yoke on the fat part right below the holes for the caps. Inertia will act upon the cross and move the cap outward to lock the snap ring in place. You can check all of this very simply. Once you get the joint installed, move it back and forth and you can feel the tightness from one side being shoved against the thrust bearing inside the cap. After you set both side back against the snap rings, it will free up the joint in a most noticeable manner.

- You should also try to rotate the snap ring in the groove with the end of a screwdriver by pushing on it. If it doesn’t spin easily, that’s good enough.

- Also why you see folks struggling to remove the snap rings. They don’t understand that the previous installer did it correctly and they need to release the pressure by first smacking the cap inwards before trying to pry out the snap ring and then doing the same to the other side to get that snap ring out.

steering stop adjustment

locker switches wiring

WTJF: Jeep Wrangler TJ Rubicon Factory Locker Bypass

wandering trail: locker defeat

rubicon locker bypass

Upgrading Rubicon axles: is this a crazy thought? | Page 2 | Jeep Wrangler TJ Forum

ElectricWizards 2000 TJ Sport Build | Page 12 | Jeep Wrangler TJ Forum

The idea is to insert a relay to interrupt the momentary ground that the pcm needs to enable both the lockers and the dash light circuits. If you wanted to enable lockers on all tcase positions, you have to do the wandering trail mod on top of this.

Tailgate Dome Light Activation Switch

Tailgate Dome Light Activation Switch

ac defeat

JF: For the A/C Guys

WTFJ: jjvw post

winch stuff

Roundforge: Warn M8000 buyers guide

TRE Winch Rope

Winch Master Disconnect | Jeep Wrangler TJ Forum

WTJF: Warn Midframe Winch Resource Thread

Wizard Recovery Gear!

Wizard Recovery Gear - ST FAIRLEAD

Wizard Recovery Gear - STANDARD HAWSE FAIRLEAD

Thimble and rope coming soon

Which winch? | Jeep Wrangler TJ Forum

warn m8000

warn m8000 | summit warn m8000-s | summit

winch plate

Winch with stock bumper? | Jeep Wrangler TJ Forum

WARN 37170 Winch Mounting Plate for 97-06 Jeep Wrangler TJ & Unlimited | Quadratec

Warn 37170 winch plate | summit

LoD Offroad JWP9654 Bolt-On Winch Plate for TJ | Quadratec

LoD Offroad | TJ Bolt-on Winch Plate

Smittybilt 2802 SMI Raised Winch Plate for 87-06 Jeep Wrangler YJ, TJ & Unlimited | Quadratec

Fishbone Offroad FB21052 Winch Plate TJ with Fishbone Offroad Piranha Front Bumper | Quadratec

front bumpers

WARN 87700 Rock Crawler Stubby Front Bumper for 97-06 Jeep Wrangler TJ & Unlimited | Quadratec UCF aluminum bumper with fairlead UCF steel bumper with fairlead SAV-TJF - Savvy Off Road Front Bumper TJ/LJ 1997-2006 - Savvy Off Road

XD9000i rebuild info

Warn XD9000i for repair | Jeep Wrangler TJ Forum

- 83665 remote $82

- 77892 motor $210-260

- 72631 solenoid $32 each (need 4)

- 32455 brake $140-160

- Misc parts $40ish

Warn XD9000i | Jeep Wrangler TJ Forum

Montanajacks had all the parts I needed in stock.Warn winches – Montana Jacks Outpost

spooling line

Do a locked Brummel eye about 14" in from the end of the line and leave the tail out after a very short bury. Make the eye large enough for the end terminal (thimble or hook) to fit through. Eye goes over the top of the drum, around the backside, out forward under the drum. Other end goes through the eye, snugs up tight against current anchor side, tail lays across drum and gets taped down and cut to length drum width. As soon as you tension it, it will snug up tight but no matter what, you can’t pull the line loose from the winch if you screw up.

How to Re-tie a Locking Brummel Loop at the end of your winch-line WITHOUT unspooling your winch!! - YouTube

WTJF: winch line to drum attachment WRG

Brummel lock-splice with one side fixed - YouTube

in cab winch controllers

What winch panel switch are people using? | Jeep Wrangler TJ Forum

Control box relocation

Relocating winch control box | Jeep Wrangler TJ Forum

MountaineerTom’s 2006 Jeep Wrangler Unlimited | Page 6 | Jeep Wrangler TJ Forum

new soft top

Sierra Offroad 2003-2006 TJ Wrangler Soft Top with Tinted Windows, Black Trilogy Acoustic Vinyl

radio amp

Crutchfield: Soundstream Picasso Nano PN5

Amazon: Soundstream picasso nano

WTJF: SSTJ build notes

wiring examples

mount examples

WTJF: How to install a subwoofer amp under steering column

WTFJ sourbluff mount

WTJF Nashville install

subwoofer wiring examples

Goldwood GW-S650/4 6-1/2" Poly Cone Woofer 4 Ohm

Kicker 48CWRT674 CompRT shallow-mount 6-3/4" subwoofer with dual 4-ohm voice coils | Crutchfield

The Soundstream’s sub channel is rated at 350 watts at 2 ohms (or 200 watts at 4 ohms), so the Kicker subwoofer I would recommend is a 1 ohm or 4 ohm version, but not the 2 ohm version. The 1 ohm can be wired in series which will draw 2 ohms/350 watts, or the 4 ohm can be wired in parallel and draw the same 2 ohms/350 watts.

clutch

HF: Three Jaw Bearing Puller

Amazon: E12 socket

Amazon: Luk clutch kit

Amazon: Omix-Ada Clutch Fork

Timken 614093 Clutch Release Bearing

National 614093 Clutch Release Bearing Assembly

HF 450 lb. Low Lift Transmission Jack

WTJF: NV3550 throwout bearing and clutch replacement advice

WTJF: Clutch recommendations and tips?

This is a bolt-in job, there’s not much to it. Just know that there’s usually no reason to have to replace the flywheel unless it is physically damaged. Also, don’t have the surface of the flywheel resurfaced or refinished. The TJ’s flywheel has a domed surface that would be removed if it was resurfaced. At the most, if it has any glazing on its surface, just remove it with a mild grade of sandpaper or emery cloth.

About the only thing not included in that kit that I’d recommend would be a different throwout bearing than what is included.

Transmission impossible (2002 Jeep wrangler TJ) - YouTube

Removing pilot bearing TJ Jeep Wrangler - YouTube

TJ jeep shifter disassembly - YouTube

Jeep TJ wrangler Clutch install debriefing - YouTube

NV3550 shifter overhaul Jeep TJ wrangler 5 speed - YouTube

TJ Jeep trans mount overhaul - YouTube

Flywheel 2.0 and Clutch (jeep wrangler TJ 4.0L) - YouTube

Jeep Transmission install - YouTube

Jeep Clutch Repair on a 2000 Jeep Wrangler 4.0 / Transfer Case Removal Walk Though - YouTube

4x4xplor 1997 Jeep TJ Clutch Replacement

NV3550 throwout bearing and clutch replacement advice

For the pilot bearing, use bread. I’ve used this trick three times now on different engines, works every time: pack the hole full of bread, take a 3/8 extension or a punch, wrap electrical tape around it until it’s the same diameter as the hole, to act as a “seal”. Keep hammering the extension into the hole. Stop and repack with bread as it gets compressed. Eventually, it’ll pop right out.

Ive heard of people doing the same thing with grease, but bread is a lot easier to clean up than grease once the bearing pops out.

rain cover

rebuild front driveshaft

5-793x - shaft to pinion yoke ujoint

5-1330x - cv ujoints (2)

Denny’s driveshaft rebuild kit

Replacing Front Driveshaft Double Cardan U-Joints on Jeep Wrangler TJ Dana 30 - YouTube

03-06 TJ Rubicon factory DS

Front Drive Shaft (stock)

- U-Joint @ Diff: Spicer 5-793x

- U-Joint @ DC Joint (x2): Spicer 5-790x (5-1330X)

- Non-Greasable Centering Yoke Spicer 211996X

- Centering-ball Seal: Spicer 2-86-418

- U-Joint Strap Kits Spicer 2-70-18X

- T-case Bolts 6036415AA

04 Rubicon front driveshaft u-joint issue. What am I missing here? | Jeep Wrangler TJ Forum:

TJ Rubicon front driveshafts use a nylon injection to hold the axle end yoke u-joint in place. There are no snap rings or c-clips. You heat up the yoke and the nylon literally shoots out the injection hole. Once removed, clear the channel where the nylon was and use inner c-clips with the replacement u-joint.

Correct front drive shaft u-joint? | Jeep Wrangler TJ Forum

flip door handles

WTJF: How to Reverse TJ Door Handles

repair mf switch fog lights

WTJF: How to repair multifunction switch for fog lights (fog lights that won’t turn off)

h4 headlight conversion

WTJF: Cheap Toyota H4 Conversion Kit

ball joints

youtube: inner axle seals

WTJF: Wrangler TJ Ball Joint Replacement

youtube: jeep ball joint replacement

WTJF: Ball Joint Tool Kit

Amazon: spicer 706944X ball joint kit

How to Replace Ball Joints in a Jeep Wrangler - YouTube

tools

Press:

people really like the OTC kits, but they are pricey

DHA Ball joint press kit

OTC 7249 ball joint press

Amazon OTC Ball Joint kit

HF: Ball Joint Service Kit

orion press kit

Adapter kit:

The trick for the ball joints is the 7894 adapter kit (amazon)

OTC 7894 ball joint adapter kit

Amazon OTC Jeep/Dodge Joint service adapter

amazon Sunluway adapter kit

alignment

How to align your Jeep Wrangler TJ

set your toe-in so the fronts of the tires are 1/16" to 1/8" closer together in front than in the rear

Re-centering the steering wheel is required whenever the toe-in is adjusted or when the suspension height changes. That is easily done by rotating the short adjustment link on the drag link after loosening its two clamps.

241 rear seal fix

TSB # 21-003-04: Leaking NV241 transfer case on TJ Rubicon models

PARTS

Retainer, t/case rear (includes rear output shaft seal) 05093606AA (1)

Washer, t/case rear output shaft sealing 04210973 (1)

Seal, vehicle speed sensor 05093612AA (1)

Nut, t/case rear flange 04167924 (1)

Sleeve, rear flange wear (seal slinger) 05093605AA (1)

RTV, Engine Sealant 04883971 (1)

Fluid, transmission/transfer case (ATF+4) 05013457AA (3)

sliders

WTJF: Rock Sliders / Rocker Guards Guide

raise gas skid

WTJF: What is involved in lifting the gas tank one inch?

WTJF: JMT build thread gts clearance mod

front brakes

front left brake shield

front right brake shield

BMB: TJ Brakes

BMB: Front pads and rotors

BMB: Front calipers

BMB: VANCO 15" Big Brake Kit with Unit Bearings

unit bearings/hubs

Article: Axle U-Joints & unit bearings

Amazon: Timken bearing hub

Wrangler TJ wheel hub / bearing assembly replacement

WTJF: How to Install a Jeep Wrangler Front Axle U-Joint and Hub

WTJF: ElectricWizards 2000 TJ Sport Build

stuck Unit Bearing - TJ Generation

WTJF: Can’t remove front axle, any tips?

hub/bearing assembly bolts torqued to 75ft/lbs

Amazon: Timken HA597449

front axle nut - 36mm torqued to 175 ft/lbs Amazon: dorman 05101 kit

how to guides and info

Wrangler TJ wheel hub / bearing assembly replacement

troubleshooting

stuck Unit Bearing - TJ Generation

WTJF: Can’t remove front axle, any tips?

stuck hub:

- Put a 2.5 inch wide tube, a big bolt, whatever behind the outer stub axle and the inner C and use the steering wheel to push the bearing out.

- beat on the 12 point bolts with 12 point socket too and drive it out

Stu: unstick that unit bearing

subwoofer unit

Amazon: JBL BassPro Nano 6" Powered Subwoofer

Amazon Sound Ordnance B-8PTD 8" Powered Subwoofer

WTJF: SSTJ build notes

JF Archive: easy console sub

oil pan and gasket

youtube

Oil pan removal jeep TJ wrangler - YouTube

Jeep 4.0L Oil pan strap refurb (hard to find part) - YouTube

Oil pan reinstalled Jeep TJ 4.0 - YouTube

aim headlights

Daniel Stern aim headlights

WTJF: How to aim and align your headlights

How to aim and align your headlights | Jeep Wrangler TJ Forum

Screwing the bottom screw clockwise will move the beam toward the passenger side.

Screwing the top screw clockwise will move the beam up.

flush brake fluid

WTJF: School me on flushing brake fluid

WTJF: Questions about flushing brake fluid

WTJF: Brake Fluid Change

WTJF: Blaine - Doing a brake job? MUST READ!

How to bleed your brakes

Two quarts of DOT 3/4 is what you need. Start by using a turkey baster to suck the old dirty fluid out of the brake reservoir.

On a system that’s never been bled before you may find yourself running 64oz+ through it to get clean fluid. You can do this initial bleed to get clean fluid one person, once it’s clean you’re going to need a second person to help. If you don’t, air can get past the bleeder threads. Don’t let the MC run dry.

Don’t store open brake fluid, once you open a container it needs to be used.

If you need more than 5-7 bleeds per corner, stop and find the problem because flushing more fluid down the drain isn’t going to fix the problem.

Open screw, pedal to the floor hard and fast, close screw, let pedal up, repeat.

timing chain

WTJF: Do I need a new timing chain?

WTJF: How to replace the timing chain on a Wrangler TJ 4.0

Cloyes Kit Summit

Chain MOPAR 53020444

Crank Sprocket MOPAR 53020443

Cam Sproket MOPAR 53010557AA

cooling system

Drilling a hole into the thermostat’s flange like shown below and positioning the hole at the top when installing it will help get rid of the trapped air more quickly. Some thermostats come with a vent hole already, just make sure to position it at the top when installing it.

To remove fan:

To install fan:

US Motor Works 22160 fan clutch

constant tension clamps

coolant system fill kit

full parts list

2000-2006 (4.0 liter 6 cylinder)

- Waterpump: 5012366AG

- Water Pump Inlet Tube

- Thermostat: 52028186AC

- Thermostat Gasket

- Thermostat Housing 53006192

- Radiator:

- MT 55037652AA Amazon

- AT 2000-2004: 55037653AB Amazon

- AT 2005-2006: 55037653AC Amazon

- Summit CSF 3244

- RockAuto SPECTRA PREMIUM CU2101

- RockAuto DENSO 2219234

- Upper Radiator Hose 52028264AB

- Lower Radiator Hose: 52079670AA

- Fan Clutch: 68064765AA

- Radiator Cap:

- Coolant Reservoir

- Idler Pulley

battery

AGM battery

WTJF: Odyssey Northstar or Diehard

Odyssey

$240 Napa Legend AGM

$220 Oreilly SuperStart platinum AGM group 34

- $158 Oreilly: Super Start Marine AGM Group Size 34M Top Post Battery

- $135 Sams Duracell AGM Deep Cycle Marine and RV Battery, Group Size 34M

- $190 Sams Duracell AGM Automotive 34

- $190 Sams Duracell AGM Automotive 34/78

duralast platinum agm Auto zone

diehard platinum agm

$350 x2 power

northstar

“Calcium” AGM like the offerings from NAPA, O’Reillys, Duracell, etc., - good batteries at a more reasonable price point and suitable for most jeepers looking to upgrade from a flooded lead acid battery who either can’t afford the price point of a Northstar or don’t need the features of a pure lead AGM battery. I will probably buy one of these as my next battery

East Penn vs northstar

differences between “thick plate calcium AGM batteries” such as the offerings by East Penn, and “thin plate pure lead AGM’s” which include Northstar, Odyssey and Optima. The article concludes:

“Both the calcium AGM and the pure lead AGM crank longer and are more tolerant of deep cycle drains than OE maintenance-free batteries. That said, there is a performance difference among these two types of AGM battery. Since the thinner plates in the pure lead AGM have more surface area contact than the thicker plates in the calcium AGM, they are more efficient during both discharging and recharging. The calcium AGM is ‘better’ while the pure lead AGM is ‘best.’”

See: http://www.hendonpub.com/law_and_order/articles/2015/04/agm_battery_technology

It appears from the article that in the hierarchy of AGM’s the Napa Legend is better than a flooded lead acid battery but not in the same category as a pure lead AGM battery such as Northstar, Odyssey and Optima. It also explains the substantial price difference between the East Penn offerings and those of the other AGM manufacturers.

Be sure to get a Group 24 instead of a group 34 for the extra capacity.(?)

34 is original

24 is taller, more capacity but lower amps

78

East Penn or Deka dealer near you and get an Intimidator 9A78DT. Should be able to find them in the $250 range.

center axle under jeep

WTJF: center axle with adjustable track bar

set bump stops

WTFJ: bump walk through with pics

WTFJ: How to set your bumpstops

RMS

This is very, very true! Anyone installing a RMS should make sure to use the supplied plastic tab, to ensure the top seal doesn’t get knicked. I’ve learned this one the hard way and had to make a trip to the part store for a second seal kit. Also, care has to be taken to ensure both the upper and lower halves are installed correctly, with the small lip facing forward.

Getting the pan off, with the front Dana 30 or 44 in place, requires unbolting the shocks, dropping the rear as far as it will go, and loosening the exhaust bolts, so the pan will clear.

WTJF: rms replacement

rear main seal 2002 TJ Jeep Wrangler 4.0L - YouTube

Tools and Parts Needed

- High Temperature RTV - https://www.amazon.com/dp/B0002UEN1A/?tag=wranglerorg-20

- Oil Pan Gasket - https://www.amazon.com/dp/B000C2AMQ8/?tag=wranglerorg-20

- RMS Gasket

- Amazon rtv 4318083 (Anaerobic! Not your average RTVs! It is not cheap but required, ~$16 from dealer. - No parts stores carry this item.)

- Amazon: Paint Prepping Solvent

- Sockets and Ratchets with extensions

- Torque Wrench

- 6qts. of Engine Oil

- Oil Filter

Torque specs bearing race 80 ft/lbs starter motor 33 ft/lbs girdle 35 ft/lbs oil pan bolts

- 1/4 inch bolts - 84 in/lb

- 5/16 inch bolts - 132 in/lb

valve cover gasket

WTJF: changing valve cover gasket

WTJF: valve cover gasket replacement

WTJF: 2000 valve cover gasket

WTJF: rtv example

I just used RTV on the corners.

The FSM for my 05 stated 10 Newton meters.

wiring bridge WTJF: how to remove plastic wiring bridge

Page 1019 INSTALLATION The cylinder head cover is isolated from the cylinder head via grommets and a reusable molded rubber gasket. The grommet and limiter are retained in the cylinder head cover.

- If a replacement cover is installed, transfer the CCV valve grommet and oil filler cap from the original cover to the replacement cover.

- Install cylinder head cover and gasket (Fig. 14). Tighten the mounting bolts to 10 N·m (85 in. lbs.) torque.

- Reinstall the plastic wiring loom trough at the rear of cylinder head cover.

- Reconnect the left hand side of the wiring harness loom to all components.

- Connect the CCV hoses.

- Install control cables and bracket on intake manifold and tighten bolts to 8.7 N·m (77 in lbs.) torque.

- Connect control cables to throttle body linkage.

- Snap control cables into cylinder head cover clip.

- Connect negative cable to battery.

fix blend door

grease front end

There are seven total zerks. 2 upper ball joints, the track bar frame end, and 4 in the steering ends.

TJ Grease & Lube Fittings - TJ Generation

Grease recommendation | WTJF

Lucas Red’n tacky

Lucas Oil 3 oz. Red N Tacky (3-Pack) 10318 | Home Depot

Lucas Oil 14 oz. Red ‘N’ Tacky Grease 10005 | Home Depot

service johnny joints

I have 16 johnny joints.

9 2.5" - 8 on the 4 lower cas, 1 on the frame end of the front track bar

7 2" - 6 on the 4 upper cas, 1 on the diff end of the front track bar

grease

moly grease for RCVs? - johnny joints

Red Line Synthetic Grease 80402

Red Line Synthetic Oil. CV-2 Grease

CE-9013G - Johnny Joint® Grease

tools are $200+, two sizes needed for the uppers and lowers.

budget option is all thread rod and sockets

Johnny Joint Maintenance | Page 4 | WTJF

@rasband: All thread (or a long bolt), a cup that the housing can rest against, and a socket that is big enough to go around the bolt hole and rest on the washer on the snap ring side.

mr blaine: Johnny Joint Maintenance | WTJF

Two things are key. First, the socket you use to push in the washer to take the load off the snap ring needs to be larger than the hole in the washer by enough not to tilt into the hole. It also needs to be smaller than the amount of room that it takes to pop the snap ring out of the groove. You can grind a flat on one side to give the snap ring eyes room to pop out.

The second thing is when you using all thread to squeeze the washer, the opposite side needs to be on the body, not the other washer. Otherwise, you can move the wrong washer or really have to squeeze the races towards each other in hopes that the one under the snap ring moves. React against the body opposite the snap ring and it all works much better.

rasband | Jeep Wrangler TJ Forum:

JJ balls have a small line around the collar of one of the two sides. This signifies the side that should be facing the snap ring. This is to note the side that’s marginally longer to account for the snap ring added on that side. It’s slight, but measurable at 1/16” on a 2.5” JJ.

Sharp washer edge goes away from the rubber bushing

same with the snap ring, sharp side faces out

Tools:

- Vise

- Big snap ring pliers

rockjock:

CE-9110T - 2 1/2” Johnny Joint® Assembly/Disassembly Tool

CE-9112T - 2” Johnny Joint® Assembly/Disassembly Tool

ebay:

CE-9110T - 2 ½” Johnny Joint® Assembly/Disassembly Tool | eBay

CE-9112T - 2” Johnny Joint® Assembly/Disassembly Tool | eBay

bolts

check for drilled balls when disassembled. if balls are drilled, it can accept grease from drilled bolts.

greaseable bolts for johnny joints

CE-91107 - 9/16" Greaseable Bolts for Currie Johnny Joint - Savvy Off Road

rock jock Greasable Bolts

how to guides

How-To Rebuild a Johnny Joint - YouTube

How To Rebuild Johnny Joint, With or Without the Expensive Rebuild Tool! - YouTube

Rebuilt | Currie Johnny Joint - YouTube

How to Rejuvenate a Worn Out Johnny Joint | Jeep Wrangler TJ Forum

track bar grease fittings are 1/4-28 threaded

Precision 1/4-28 Inch flush Grease Zerk 621 | O’Reilly

1/4-28 Flush Straight Grease Zerk Fitting 5 Pcs

Metal Grease Fitting Plugs | Huyett

front component speakers

KICKER | KS Series 5.25" Components KSS504 or KSS50

Kicker 47KSS504 KS Series 5-1/4" component speaker Crutchfield

Upgrading the sound system on your Jeep Wrangler TJ | Page 46 | Jeep Wrangler TJ Forum

stereo head unit

Clarion M508 Marine | Crutchfield

Kenwood Excelon KMM-X704 | Crutchfield

Kenwood Excelon KMM-X705 | Crutchfield

regear

Grimm Jeeper Gear Ratio Calculator

thinking 4.88s for my nv3550 and 33s

this is what i had in my ‘01 with 35s and it was fine.

ratio math

NV3550/29.53"/4.10=2729rpm @ 75mph

NV3550/31.86"/4.10=2529rpm @ 75mph

NV3550/31.86"/4.88=3011rpm @ 75mph

NV3550/31.86"/5.13=3165rpm @ 75mph

NV3550/33.50"/4.10=2406rpm @ 75mph

NV3550/33.50"/4.88=2863rpm @ 75mph

NV3550/33.50"/5.13=3010rpm @ 75mph

how to

Regearing from 4.88 to Revolution Gear’s new 5.38… sweet! | Jeep Wrangler TJ Forum

- After removing the carrier, the existing pinion gear depth was measured using the bearing cap seating surface as a reference point. That gave a very good preliminary depth from which to set the new pinion gear depth. Setting the pinion gear depth involves shimming it in/out with shims included in the master install kit.

- we’re measuring down to the thousandth of an inch.

- It requires a bearing puller to pull the carrier and pinion bearings off. The bearings have a TIGHT fit so they require a bearing puller powered by an impact wrench. It takes a while for the bearing to finally come off even with this setup.

- Installing the ring gear requires Loctite be applied to the new ring gear bolts. That prevents the bolts from backing out which can destroy pretty much everything inside the housing. Some use blue Loctite but we used red which is more secure. Revolution’s ring gear fit over the Rubicon locker snugly/perfectly without needing to heat the ring gear and freeze the locker/carrier as some require.

- Pressing the pinion bearings using a hydrolic press

- Reinstalling the Rubicon locker reuses the Rubicon’s OE carrier shims to position it left/right to create the right amount of backlash between the gears. Too little backlash between them can cause insufficient lubrication between the gears and damage the tooth surfaces, too much backlash reduces strength. We ended up with the backlash being right on at .008, same as it was originally.

- This pic shows using a brass punch to tap in the shim. Using brass here eliminates damage to the shim. Just be careful you get the same shims back in the same sides they came out of.

- Painting the gear marking compound onto the gear teeth.

- Part of the setup procedure requires setting the pinion bearing preload which requires a small 1/4" drive in-lbs. bar-indicator torque wrench. Revolution specifies between 14 and 19 inch-lbs. of resistance required to rotate the pinion gear. We ended up right at 18 inch-lbs.

- Checking the final backlash between the gears. Revolution Gear specified .006 to .010, we ended up at .008.

- One thing about the Rubicon’s locker and sensor, you have to pay attention to getting the carrier and sensor situated correctly together. With help from Brook at RGA and danb303 and TJR238 here on JF, I used the “toothpick” technique to fully extend the sensor’s pin out far enough to clear and avoid damage while inserting the locker back into the housing.

- Once the locker is back in place after the final pattern and preload adjustments have been completed, you pull the toothpick out with the fishing line tied to it. That releases the sensor to seat properly behind the locker’s actuator plate. However, this is only a concern if you have a Rubicon.

Tools needed

The only specialized tools required include a press for the new bearings, bearing puller, dial indicator for the backlash setting, a ½” torque wrench, and an inch-lbs. beam-style ¼” torque wrench for setting the pinion bearing preload.

Rubicon info blerbs

“Thick” gear sets are what you need for your Rubicon lockers and X2 on the recommendation for Revolution Gear & Axle’s gears. For 35’s X2 for 5.38 if you’re running the automatic, definitely.

revolution 4.88 gears from allens offroad

Note the ‘Thick’ ring gear designation on the label. That means they fit and work with the Rubicon lockers made to work with higher (lower number) ratios. A conventional non-thick 5.38 ring gear will not work with the TJ Rubicon lockers.

rubicon info threads

Gearing down stock Rubicon carriers | Jeep Wrangler TJ Forum

Gearing recommendation for 2003 Rubicon with manual transmission and 35" tires? | Jeep Wrangler TJ Forum

Thick Cut Gears vs. Thin Cut Gears (and Axle Carrier Breaks Explained) | Jeep Wrangler TJ Forum

Ring and Pinion Break in Procedure

When installing a new ring and pinion it is recommended to properly break in the new components. The proper break in procedure will extend the life of the components and help with the prevention of premature failure usually caused by extreme heat.

Although your new ring and pinion is “Lapped” from the factory for smooth quiet operation, they will still need to be broken in once they have been installed. A new ring and pinion will initially run hotter when new and can cause extensive damage if the temperature exceeds ideal operating conditions for an extended period of time. The suggested break in procedure is as follows:

- The first drive with the new ring and pinion should be under normal driving conditions (No hard starts, No racing, No off-roading, No towing and not at Highway speeds).

- The vehicle should be driven 15-20 minutes around town, normal stop and go driving. Then you should let the axle assembly “Completely Cool” (this will allow the gear oil to cool down so it does not reach temperatures that will break down the oil, causing loss of protection)

- Repeat the 10-15 minute drive and cooling off period 2-3 times

- Then you will want to drive on the highway and repeat the process at least 2 times abiding by local speed laws but not exceeding 65 MPH, be sure to let the axle assembly completely cool between drives (very important).

- Lastly you will want to change the gear oil after the initial 500-1000 miles and your gears are broken in correctly. Note: If vehicle will be used for towing, repeat the break in procedure the first time it is used to tow.

Follow the factory service manual for recommended differential service intervals unless the vehicle is used in extreme conditions on a regular basis, you will want to service the differential more often.

(Recommended gear oil is an 85-140W, Non-Synthetic, GL5 grade or Higher, Name Brand Oil. Please note extreme weather conditions may require alternative weight oil so be sure to consult a local mechanic or lube technician for recommendations)

gearsets

Motive Gears

Motive Gear Jeep TJ Rubicon, 4.88 | Morris 4x4

Motive Gear Jeep Rubicon 4.88 Gears MGK-116 | extreme terrain

Motive Gear Rubicon 4.88 | Quadratec

Revolution gears - Rev-TJ-Rub-488

Jeep TJ Rubicon Gears Revolution Gear & Axle

Koyo Rev-TJ-Rub-488-K | eBay

Timken Rev-TJ-Rub-488 | eBay

https://www.amazon.com/Revolution-Gear-Axle-overhaul-carriers/dp/B01ETJQZCY

Revolution Gear & Axle TJ Rubicon | POLY PERFORMANCE

Jeep TJ Rubicon 4.88 Timken | rwkhaus

Jeep TJ Rubicon 4.88 ratio Koyo | King Off Road Parts

Jeep TJ Rubicon 4.88 Timken Rev-TJ-Rub-488 | vividracing

Yukon gears

Yukon Gear Jeep TJ Rubicon, 4.88 ratio | ecgs

Nitro Gears

Nitro Gear set

rear axle seals

9912S

Leaky rear axle seal, what’d I mess up? | Jeep Wrangler TJ Forum

Edit: the one on the right is SKF 18731

SKF 18731 Grease Seals

Timken 9912S or Dana 35239. The Dana would have been factory, the Timken is a different design with an expanding skirt that tightens up into the tube bore when you crank Down the retainer plate nuts. Helps prevent leaks. Many fans of the true 9912s here. Just don’t order the 9912S from Amazon because you’ll get fake crap. Order from rockauto. BTW, to find axle seals on rockauto, you need to go to “brake and wheel hub” and then to the “wheel seal” section. they

Rear Dana 44 axle seal | Jeep Wrangler TJ Forum

X2, you need to remove the existing bearing and bearing retainer to place the seal. You want a SET10 bearing set, the Timken 9912S from rockauto, not amazon is the right choice for the seal.

The old bearings are removed by drilling a big hole in the bearing retainer, stopping the drill bit before it reaches the axle shaft. A cold chisel across the hole will break it so it can be removed.

Then you’ll need a press to install the new SET10 bearings, seal, and bearing retainer. It should look like this once they’re pressed into place. This shows the disk brake type of axle retainer bracket, the one for drum brakes is flat without the flange.

fuse and relay

Fuse box diagram Jeep Wrangler TJ and relay with assignment and location

zj tie rod/steering

https://wranglertjforum.com/threads/zj-steering-upgrade.11895/

https://wranglertjforum.com/threads/zj-tie-rod-conversion.2373/

https://wranglertjforum.com/threads/what-is-the-best-steering-for-my-jeep-wrangler-tj.2956/

Did MOOG screw up? | Jeep Wrangler TJ Forum

tie rod only

(1) ES3096L End

(1) ES2079S Sleeve

(1) DS1312 Tie Rod

Torque Specs

Drag Link to Pitman Arm Nut - 81 Nm / 60 ft.lbs.

Drag Link to Knuckle Nut - 47 Nm / 35 ft.lbs.

Drag Link Clamp Bolts - 49 Nm / 36 ft.lbs.

Tie Rod Clamp Bolts - 49 Nm / 35 ft.lbs

Tie Rod Knuckle - 47 Nm / 35 ft.lbs

Tie Rod to Drag Link - 75 Nm / 55 ft.lbs.

service front diff

75w-140 gl-5

1.89 L (4.0 pts.)

Diff cover bolts: 30 ft.lbs

Diff fill plug: 25 ft.lbs.

frame drain holes

5/16 or 3/8. I drilled 1-1/2 inches away from each control arm mount.

5/8 in the usual positions, after drilling a pilot hole I used a step drill.

it’s either 1/2” or 5/8” for it to drain. if the hole isn’t big enough then the surface tension of the water will prevent it from running out

Drill 5/8” drain holes about 3-4” behind the front control arms brackets. Absolutely!

1/2” is good. Some go to 3/4”. Anything in there is fine.

15mm hole centered 117mm behind the front control arm mounts

looking like 5/8 is the right size

rear crossmember drain

frame clean out

I sit a fan type water sprinkler that goes back and forth under the jeep in various places for 15-20 minutes at a time for a total of a couple hours once I get back. Then I use this with my pressure washer. Under carriage clearer

Last, I use my water hose and shoot water into the frame at every hole I can find from front to back and at different angle to flush anything out.

Clog Hog® Sewer Jetter Drain Cleaner — See It in Action - YouTube

https://www.amazon.com/dp/B016Y1LIN6/

https://www.amazon.com/gp/product/B07K22DGRY

engine oil

5w30 STP conv high mileage $27

napa high milage conventional

engine oil filter filter

mopar m0-090 $10

Factory WIX 51085

Larger CJ size 51515 taller, holds more oil

electrical cables

Jeep Cables TJ Big 7 Complete Kit (Wrangler 97-06)

Custom BAttery Cables Zen 1 ga Cable Set - Big-3 Kit for Jeep TJ 1997-2006 4.0L I-6 (6 Cyl) #13027

steering skid

SAV-TJSS - Steering Box Protection - Savvy Aluminum TJ/LJ 97-06 - Savvy Off Road

Savvy steering box skid | Jeep Wrangler TJ Forum

aftermarket sway bar

REAL WORLD COMPARISON: OEM Anti-Sway Bar w/ Disconnects vs. Antirock Off-Road Sway Bar vs. SwayLOC Dual Rate Anti Swaybar System | Jeep Wrangler TJ Forum

Looking for thoughts and opinions on the Antirock | Jeep Wrangler TJ Forum

How does a Currie Antirock sway bar improve off road performance? | Jeep Wrangler TJ Forum

swayloc

Jeep TJ Sway Bar SwayLOC For 97-06 Wrangler TJ OffRoadOnly - OffRoadOnly

Off Road Only SwayLOC for Jeep TJ | POLY PERFORMANCE

Off Road Only SL-TJLV Dual Rate Manual Operated SwayLOC Swaybar for 97-06 Jeep Wrangler TJ & Unlimited with 0-8" Lift | Quadratec

setting arm angle

Do I need to pull my Antirock arm higher? | Page 2 | Jeep Wrangler TJ Forum

dead pedal

redrock dead pedaal | ExtremeTerrain

adjustable control arms

uppers 7/16" 60 ft/lbs

lowers 9/16" 90 ft/lbs

seat bushings

Seat Bushings | Jeep Wrangler TJ Forum

Seat Bushing Repair Jeep Wrangler TJ LJ Front Seats - YouTube

Hillman from lowes

Nylon spacers:

- 3/4 x 1/2 x 3/8 | 880447

- this slides over the upper stud to hold the cut nylons pacer in place (B)

- 1/2 x .257 x 1 | 880438

- cut down to the length between the seat frame and button head. cut in half to sandwich over the shaft. (A)

- 1/2 x .385 x 1 | 880441

- 1 x 13.32 x 1/16 | 881539 flat nylon washer

T40 torx

small pipe cutter?

craftsman tiny ratchet set

super glue gel

file

needle nose pliers

(A):

(B):

(C):

(D):

(E):

defrost only fix

Air won’t come out of vents? Read this! | Jeep Wrangler TJ Forum

How to fix heat / AC / air not blowing through center vents | Jeep Wrangler TJ Forum

Only blows out the defrost | Jeep Wrangler TJ Forum

Defroster control not working | Jeep Wrangler TJ Forum

HVAC air only blowing through defrost vents | Jeep Wrangler TJ Forum

Fsm

24-2

24-16-18

24-38

replace factory diff side air fitting

How To Replace Rubicon Axle Air Fitting | Jeep Wrangler TJ Forum

factory diff air fitting

diy quick discos

DIY Quick Disconnect Pins (bolted) | Jeep Enthusiast Forums

clean IAC

Basically start the engine then spray throttle body cleaner into the throttle body at idle rpms. The IAC will only draw the cleaner in through itself when the engine is at idle. The cleaner will flood the IAC so the engine will die. That’s ok, just restart the engine. Plus the extra time the cleaner sits inside the IAC after the engine dies and before you restart it helps it work.

No guarantees of course but thoroughly cleaning the IAC usually fixes this kind of problem. My goal is to get 1/3 of the can of TB cleaner through the IAC.

How to clean your IAC (Idle Air Controller) valve | Jeep Wrangler TJ Forum

actually removing the IAC to clean it is seldom required. When cleaned as suggested above, the IAC usually pulls in enough cleaner through itself to restore it back to good operating condition.

diagnose hard start

fuel pump | Delphi FG1353 | Diagnosing Hard Start Issue | Jeep Wrangler TJ Forum

Difficulty starting | Jeep Wrangler TJ Forum

new starter

new starter installed2022-09-17 @ 136,130mi

reman unit from oreilly’s on 407

chromoly axle shafts

Jeep TJ / LJ / YJ / XJ Axle Kits | Carbon Off Road 4340 Chromoly Jeep Axle Kits

Rear Locker Discussion | Jeep Wrangler TJ Forum

Jerry Bransford: good quality 4340 30 spline shaft like from Revolution Gear or Superior Axle

fronts

30 spline inner/27 spline outer

4340

Chromoly Shafts - Front - Dana 44

Motive Gear Ten Factory Shaft Kit Summit

rears

30 spline

4140

DANA 44 REAR TJ CHROMOLY SHAFT KIT (97-06)

Motive Gear Ten Factory Shafts Summit

arb air lockers

ARB Lockers in TJ Rubicon | Pirate 4x4

RD116 or RD117?

To install an ARB for TJ Rubicons ‘03-‘06 WITH the thick gear set, you need an RD117 front & rear.

More specifically, you need an ARB with differential case # 013005 and flange cap assembly # 027305. That means that if you want to upgrade your rear to a 35 spline dana 44, then you need to find the ARB with this case and flange cap assembly (all other internal parts are the same). NOTE: on ARB’s product guide it will say “Dana 44, 35 Spline, 3.73 & DN” for the ARB you need with the thick gear set. It doesn’t say anything about Rubicon’s, other than “call ARB” (which I found on another product sheet BTW). However, this is the correct locker even though it states “3.73 & down”, because of the thick ring gear, and if you have a Rubicon, then you know that your gears are 4:10 & up.

To upgrade to a 33 spline D44 for the rear, you will need to contact ARB to have them assemble the correct one for you, since it’s not a production locker they list as of yet. You still need the case & flange cap assembly as stated above.

So here’s what the part numbers break down to for TJ Rubicon’s with the Dana 44 thick gear set:

- 30 Spline (front & rear): RD117

- 33 Spline (rear): call ARB

- 35 Spline (rear): RD147

Now, if you re-gear AND do an ARB at the same time, you can just get the normal 44 ring & pinion and normal ARB as listed on their product guide. However, I re-geared to 4:88 with the stock lockers, so I had to re-gear with the thick ring gear….which is how I ran into all this when I later installed the ARBs with the thick ring gear I already had in there.

If you are ditching your air locker and regearing at the same time just skip getting thick gears. Get the gears you want in a normal set and the appropriate locker for the 3.73 and up range.

jjvw: ARB Thick Cut Gears vs. Thin Cut

Fear not! Those of us with Rubicons can change the carrier and still use thick cut gears if we want to.

ARB RD116 uses standard cut for 3.92+ gears

ARB RD117 uses thick cut for 3.92+ gears

| Part # | Differential | Ratio | Spline Count |

|---|---|---|---|

| ARB-RD100 | D30 Front | 3.73 & Up | 27 |

| ARB-RD101 | D30 Front | 3.54 & Down | 27 |

| ARB-RD117 | D44 TJ Rubicon Front | 3.73 & Down | 30 |

| ARB-RD103 | D35 Rear | 2.73 - 3.31 | 27 |

| ARB-RD102 | D35 Rear | 3.54 & Up | 27 |

| ARB-RD93 | Chrysler 8.25" Rear | All | 29 |

| ARB-RD116 | D44 Rear | 3.92 & Up | 30 |

| ARB-RD117 | D44 TJ Rubicon Rear | 3.73 & Down | 30 |

RD117

ARB RD117 Air Locker Locking Differential for 69-06 Jeep Vehicles with 30 Spline Rear Dana 44 with 3.73 and Numerically Lower Gear Ratio | Quadratec ARB Lockers for Jeep TJ/YJ/XJ/ZJ | POLY PERFORMANCE

rubicon factory lockers

![]()

shocks

Measuring for shock length and bumpstop length | Jeep Wrangler TJ Forum

@freedom_in_4low:

0. Measure the distance between shock mounts at ride height.

- put your frame on jack stands

- Remove wheels/tires

- remove shocks and disconnect sway bar

- let the axle droop all the way out and measure the distance between your shock mounts. You’ll use this later to see how much shock extension you can use.

- remove springs - if they won’t come out, remove the axle end track bar bolt to let the axle droop farther. Remove the rubber jounce bumpers from the bump stop cups.

- use a floor jack to cycle the axle all the way to full compression on each side and in the middle (to get both sides bumped at the same time. You’re looking for any mechanical contact, such as a track bar hitting a diff cover, steering hitting anything, etc. For the tie rods you’ll want to turn the wheel all the way in each direction. Measure how far your bump stops are from each other at the points where things touch that you don’t want to touch, and measure the distance between your shock mounts at the same point.

- Repeat number 6 with the tire on the side you are stuffing. Technically you can do it at the same time as #6, I just find things easier to see without a tire in the way so I separate them. Just see where the tire hits, again turning the wheel to both extremes. Note your bump stop and shock mount measurement, if it’s greater than the one from step 6.

- Go shopping for shocks. Find one that best uses your available travel as measured in steps 0, 4, 6, and 7, but puts your ride height roughly in the middle of the total travel. If the shock length you pick is longer than what you measured, you’l need to add bump stop to take up the difference, and that will cost you uptravel. If you can’t get exactly in the middle, that’s ok, just don’t farther than you have to on one side or the other. I know 2.5" of downtravel isn’t enough. Stock had 4" of uptravel so I want to have at least that.

Shock Comparison: Rancho RS5000X vs Skyjacker Black Max vs KYB Monotube | Jeep Wrangler TJ Forum

STICKY - TJ Shock & Spring Specification Resource Thread | Jeep Wrangler TJ Forum

I don’t like my Rancho RS5000X shocks | Jeep Wrangler TJ Forum

SkyJacker Black Max B8528 for the rear

shock torque specs

Front:

upper nut: 17 ft.lbs

lower: 250 in.lbs | 21 ft.lbs

Rear:

upper bolts: 23 ft.lbs

lower bolt: 74 ft.lbs

Rear Currie/Rock jock extensions:

3/8 small bolt: 35 ft.lbs

factory bolt through spacer: 85 ft.lbs

shock bolt: 85 ft.lbs

fox shocks

air filter

AC delco A1548C gold

Wix 46081

Mopar 4797777

add a trunk install

Factory rear trunk | Jeep Wrangler TJ Forum

I used four M6 nutserts and four M6x20mm (maybe 15mm?) flanged bolts with a 1.00 pitch. The instatrunk originally came with thumb screws instead of bolts, but mine didn’t have any with it and ACE did not have any in that size. I used the flanged bolts to eliminate the need for washers.

The nutserts go into the hexagon holes behind the carpet on each side. There should be grommets there. Remove them and push the nutserts in their place. It’s a tight squeeze so you’ll have to use a little force. I think I used a rubber mallet.

The nutserts are designed to expand on the inside and crimp against the sheet metal and the outer nutsert flange. You’ll need to make a “tool” to set it. I would get an M6x30mm bolt and a couple of nuts in at least grade 8 to set the nutserts. If use use a cheap grade bolt, you’ll most likely snap it with the force it’s receiving.

I used a socket on the bolt instead of a second wrench. This allows you to put equal force on the bolt and keep the nutsert straight in the hole. If the nutsert tilts to one side, it won’t set properly. You don’t have to go crazy with them though. You’re not holding on a skid plate or rocker guards.

Once your nutserts are set, you need to cut open a space for the bolts to pass through the carpet and into the nutserts. I believe the factory just cut little slits in the carpet. In hindsight I probably should have done this, but instead I used a soldering iron to “melt” through the carpet and seal the edges of the hole to prevent fraying.

Before the iron was hot, I felt around until I found the nutsert under the carpet, and poked tiny holes for reference.

Once my holes were poked, I heated up the iron and burned my bigger holes in. This melted the edge of the holes together to prevent potential fraying.

Once I had my holes burned in, I lined up the trunk and installed my flanged M6x20mm (maybe 15mm?) bolts.

on board air

How-To: Simple Onboard Air for your TJ (Viair 400H) | Jeep Wrangler TJ Forum

mounting plate

- 4.75x12" 11 gauge steel

- mousepad cushion

electrical - 10 gauge wiring

- 10 gauge 2 pole connector (ebay)

- zipcord

- blue sea 5024 fuse block plumbing

- “bar stock” brass tee

- 22" high pressure, high temp 3/8 hose

- check valve optional

- swivel stud 1/4 NPT hose

- long

- short

- pressure guage

- tee

- valve

- chucks

- etc

Viair 400h/400p

Viair 88p

existing compressor

existing compressor is a superflow or masterflow mv-50 and has a Nitto 10mm type q connector

How-To: Simple Onboard Air for your TJ (Viair 400H) | Jeep Wrangler TJ Forum

masterflow 25’ air hose

superflow Parts

speedo correction

SpeedoDRD J1

Installed 2025-03-22

Set at +4.3%

Make sure vehicle ignition switch is ON, and vehicle is NOT running.

Hold the button for 5 RED blinks then release (you will then be in Percentage Adjustment mode)

Hold the button until the LED turns GREEN then release (this selects a positive number)

Hold the button for 10 GREEN blinks then release (this enter's a 0 digit)

Hold the button for 4 GREEN blinks then release (this enter's a 4 digit)

Hold the button for 3 GREEN blinks then release (this enter's a .3 digit)

Calc page inputs: 73 GPS/70 Speedo

Jet Accuspeed:

mr blaine on install

I drill a hole in the firewall right in front of the fuse block behind the dash. Run the wires inside and then I have industrial Velcro I use to stick them right to the metal frame on the bottom of the passenger air bag. Zip it off and adjust it, put it back and it is as protected as it needs to be.

mr blaine on install

I highly prefer putting the correction device that can be dialed in by spinning a small screwdriver, stored behind the glove box with the total length of wire running from the PCM connectors to right behind the glove box. Clean, efficient, simple. Run a fuse tap from the instrument cluster fuse, ground in the same area. Total power and ground wires are about 18" long.

Yep, we drill a small hole in the firewall in front of the glove box, run a pair of wires from the correction device out through that, pick up the wires in the harness to the speedo at the PCM plugs, cut and splice and done.

more mr blaine install Since the elegant part seems to be underappreciated, here is what it looks like when done the way we do it. At the firewall, small braided loom is the tap into the PCM harness. The folded back loom is the connector for the old hood light.

rear bumper with hitch receiver

UCF aluminum hybrid rear bumper

TJ LJ YJ Low Profile Rear Bumper With 2" Receiver – Barnes 4WD

Wrangler and CJ Rear Bumper | Dirtworx

seat heaters

Dorman 628-040

(2 Seat Heaters) Dorman 628-040 Universal Seat Heater Element - Free Shipping | eBay

How-to install other heated seats | Jeep Wrangler TJ Forum

How to install Dorman heated seats | Jeep Wrangler TJ Forum

pinion angle

How much angle is too much angle for the rear driveshaft? | Jeep Wrangler TJ Forum

front

05 Flame Red TJ Build | Page 271 | Jeep Wrangler TJ Forum

fix exhaust

exhaust contacts passenger uca frame mount. the hanger attached to the trans mount needs to be shortened. B & B Muffler Lewisville

MountaineerTom: exhaust hanger mod with UCF extra clearance skid

Farmergreg: exhaust hanger mod with UCF skid

new exhaust

flat tow

https://fitmaster.roadmasterinc.com/fitmaster-results/?years=2004&make=JEEP&model=WRANGLER&type=direct https://nsarvproducts.com/pages/state-towing-laws

threads

https://wranglertjforum.com/threads/flat-tow-braking-options.32452/

https://wranglertjforum.com/threads/using-existing-truck-brake-controller-to-flat-tow-like-a-trailer.59885/

https://wranglertjforum.com/threads/flat-tow-setup-opinions.18747/

https://wranglertjforum.com/threads/how-to-install-currie-tow-bar-mounts.8972/

https://wranglertjforum.com/threads/flat-towing-my-tj.15976/

https://wranglertjforum.com/threads/how-to-properly-tow-your-jeep-wrangler-tj.2479/

https://wranglertjforum.com/threads/flat-tow-bar-for-currie-bumper.69784/

For my LJ, I went with a Blue Ox, but a simple Reese tow bar will work too.

https://www.blueox.com/product/bx7380-alpha-2-tow-bar/

I also bought a Blue Ox Patriot 3 brake system. To keep my Jeep battery charged while flat towing, I installed a Hopkins Brake Buddy battery tender. To use my Jeeps turn signals and brake lights, a Roadmaster 6 to 7 pin flex coil, and a Hopkins wiring harness.

base plate

Roadmaster RM-521424-4 https://www.etrailer.com/p-RM-521424-4.html currie tow bar mounts CE-9033TJ https://www.amazon.com/dp/B00ENZCY8Y/?tag=wranglerorg-20

tow bar

Roadmaster Falcon 2 RM-520 https://www.etrailer.com/Tow-Bars/Roadmaster/RM-520.html Blue Ox Roadmaster Falcon All Terrain, Non-Binding Tow Bar RM-522 Adapter for Jeep D-Ring Bumper Mounts to Roadmaster Motor Home Mount Tow Bars RM-035

braking

https://www.etrailer.com/tbbrake-2004_Jeep_Wrangler.htm ready brake road master even brake demco stay-n-play duo https://www.etrailer.com/p-SM99251.html Invisi-Brake from Roadmaster Brake Buddy https://www.brakebuddy.com/stealth.html Brake Buddy Classic https://rvibrake.com/products/rvibrake3-flat-towing-braking-system?variant=20046642181

safety chains

Roadmaster - RM-643 https://www.etrailer.com/p-RM-643.html

wiring/lights

https://www.etrailer.com/Tow-Bar-Wiring/Hopkins/HM56202.html Hopkins Endurance Flex-Coil Trailer Connector Adapter HM47053 Roadmaster Brake-Lite Relay Kit for Towed Vehicles RM- 88400 https://www.amazon.com/gp/product/B074RNF79R/?tag=wranglerorg-20

steering wheel

Jeep TJ Steering Wheel Upgrade - Project TJ - Ep. 28 - YouTube

Craft Customs: Steering Wheel Restoration and Customization

NashvilleTJ Wheel Wrap

5 tire rotation

fuel injectors

Precision Injectors

rockauto heat sheild

fuel pump

Bosch 69316 The Bosch 69316 comes with nothing else but the fuel pump module itself, it does not include the FPR.

rockauto DELPHI FG1221 complete pump assebly

WTJF: replace pump without replacing the whole assembly

PROCEDURE

Step 1: Grab your hammer and wood and use both to loosen the retaining ring holding the pump in the tank by placing the edge of your wood piece on a tab on the ring and hit it with the hammer (righty tighty, lefty loosey). It might take a bit, mine was on pretty tight, but keep at it and don’t use something with a sharp metal edge, or you’ll break/damage the ring.

Step 2: Remove the assembly from the tank. The assembly will have gas in it so make sure to pour it over the tank to drain it. Be careful to make sure you don’t break the sending unit float. Remove the bottom filter (it just pulls off)

Step 3: Disconnect the sending unit (circled in red below). There’s a small tab holding the connector on. Do not bend it too much, its delicate.

Step 4: You’ve probably noticed at this point that the top plastic portion is spring loaded on the aluminum housing. This is held in by three tabs (circled in green). carefully push the three tabs in past the retaining indents in the aluminum canister to free the plastic top piece. At this point, it’s not totally free. take one of your screw drivers and CAREFULLY pry the tab for the fuel pump connector and CAREFULLY pull it out.

I say carefully in all caps, because the wires for the fuel pump are most likely very rigid from years of being soaked in gas. If you’re not careful, you could break the wires and now you’re buying the whole assembly

Step 5: Set the plastic top aside and remove the spring that sits between the fuel pump feed tube and the plastic top. try to pull out this tube as well, noting which side faces up and which is down

Step 6: This is where it gets a little tricky. You can probably clearly see the fuel pump now and if you reach your hand inside the housing and grab it, it probably doesn’t come loose. this is because the fuel pump is secured to a secondary filter in the bottom of the housing (you can probably see it, it’s the small rectangular piece at the bottom) which is snapped into the housing. What ended up working for me, was flipping the housing upside down so the fuel pump was hanging in it an hitting it on the block of wood on the ground (not too hard, you’re just trying to “shock” the fuel pump out of the housing, think about smacking the bottom of the ketchup bottle and that’s about how much force you want to use).

With any luck, the pump has liberated itself from the housing! Make sure if a rubber washer and metal washer fall out, you keep track of them, they will be going back in.

Step 7: Now it’s just doing everything in reverse. Assemble the smaller filter and rubber grommet on the bottom of your new fuel pump. you may need to remove/reuse the small retaining ring from the old fuel pump. Pry it off with two flathead screw drivers and use the hammer to flatten the barbs back down for reuse. Make sure you install the new plastic spacer on the new pump and make sure you have it on the right way.

Step 8: Now install the new fuel pump. First make sure the two washers go in; rubber first then metal. If you’re having trouble here, grab a piece of wire or a straw or something skinny and long, put the washers on the wire (I used a piece of tig filler wire) and slide them down the wire into the little area in the bottom where they sit. Set the fuel pump assembly in place carefully, and using your fingers or a long, blunt edged tool and press it in. You’ll know when its “in” by holding the whole assembly upside down without the pump falling out (like the dairy queen thing)

Step 9: Now back to the plastic top. Using one or both of your flathead screw drivers, pry back the tabs on the housing releasing the retaining clip for the fuel pressure regulator (circled in blue above). Carefully remove the old one (might need to pry a little with a screw driver or plastic trim removal tool). Remove the fuel line locking tabs from the old regulator and put it on the new one. Install the new regulator (may need to use some gas to lubricate the seals) and reinstall the retaining clip.

Step 10: Reinstall the fuel feed tube on the new fuel pump, noting which side goes up. CAREFULLY re-connect the fuel pump electrical connector. Yu may need to use the edge of your screw drier to press it in so the retaining tab “clicks” in. Reinstall the spring on the tube and then slide on the plastic housing and make sure the three retaining tabs “click” past the indents in the aluminum housing. Reconnect the sending unit. Install the new external filter on the bottom of the housing.

Step 11: Remove the old gasket from the fuel tank if you haven’t already, and install the new one. Lube the inner area up with some gasoline and carefully set your newly refurbished pump/sending unit assembly in. This may take some finessing since that new gasket will be tight.

Step 12: Reinstall the plastic retainer ring (again, rightey tightey, lefty loosey); use hammer and wood block as needed.

Presto chango, you just installed a new pump and regulator without buying a whole new assembly. Go drink a beer and put your fuel tank back in the jeep!

soft top tension straps

https://wranglertjforum.com/threads/soft-top-frame-repair-top-suggestions.78294/post-1539556

https://www.amazon.com/dp/B076Y166WB

https://www.strapworks.com/3-inch-heavyweight-polypropylene-black

#8 - 1/2" screws and washers

https://www.wranglerforum.com/threads/soft-top-support-straps-hack.1218777/

https://www.jeepforum.com/threads/repairing-soft-top-frame-worn-torn-webbing.1240039/

seat foam

https://www.summitracing.com/parts/sum-rp20034-lh https://www.summitracing.com/parts/sum-rp20034-rh

brakes bench bleed master cylinder

https://wranglertjforum.com/threads/brake-issues.79525/post-1570699

Plugged port method for bench bleeding a master cylinder. I won’t type this out again so someone should save it and stick it in a readily located place for future reference.

Most BB (bench bleed) a master using the little hoses that circulate fluid out of the bore back into the reservoir. The problem with that method is it is very slow, not very effective, and tells you nothing about the condition of the master or how well you have managed to remove the air.

The PP method tells you if the master is good, whether you have the air out, and gives you a rough idea of how much you have to extend or shorten the booster push rod.

Acquire plugs that seal off the two ports in the master. If you have the little hose kit, you can put screws in the holes after you cut the little hose barbs off.

Put the master in a vise clamped ONLY on the flange. Never clamp onto the body where the bore is. Plug the ports, fill reservoir about half way with brake fluid.

Loosen the port plug closest to you and push the master PR (push rod) all the way in and hold. Close the port plug and let the PR back out. Repeat until fluid is present at that port. Close the port plug.

Move to the port furthest way and repeat the process.

Once you have fluid at both ports and the plugs tightened to seal them off, continue pushing the PR in and letting it back out until it will only allow about 1/8" or so of movement. Generally about 4-7 cycles and it will come up solid. Solid tells you there is no air in the bore. Start to finish after the ports are plugged is about 2 minutes generally.

1- that little bit of movement is important. It tells you the master is good. It is the distance the pistons move inside the bore past the ports that let fluid into the bore from the reservoir. They have to move past them to build pressure and push that out to the wheel cylinders. Otherwise, all the master would do is push fluid back up into the reservoir. 2- the ports also exist to allow the normal expansion of brake fluid as it gets warm. If the fluid can not go back into the reservoir as the fluid expands, the brakes will self apply. 3-the PP method lets you check to see if fluid is bypassing the cup seals. If you can’t get it hard to push and locked up solid after that 1/8" or so of initial travel, the cup seals are likely bad or similar. 4- some masters have 1/16" and some have a lot more. Pay attention to it so you can adjust the booster push rod as needed.

After the BB, get the crap out of the way in front of the booster, remove the vacuum seal from the master and slide it on the studs. Square it up and see what the gap is when you feel the booster gently bottom out on the booster push rod. It should be roughly about .030 or the thickness of 2 typical business cards. If it is more, you run the risk of pushing in the booster push rod and moving the cup seals past the ports. That can make it very difficult to bleed the system.

If it is less, you are adding pedal travel unnecessarily. The end of the push rod is adjustable. Grab the splined area below the hex with some needle nose vise-grips and turn the hex with a 7mm nut driver.

Once adjusted, reinstall the vacuum seal and finish the install.

This method has worked for us every single time without fail. No other way has been this effective.

brake bleeding process

https://wranglertjforum.com/threads/brake-bleeding-problem.79343/post-1567874

For the TL,DR crowd, our method is below in bold if you want to skip the rest of the drivel.

Pumping the pedal on modern masters aerates the fluid. The more you pump, the more tiny bubbles you get in the fluid. That is bad and good. Bad because fluid shouldn’t have tiny air bubbles in it, good because you can use that to tell when you have fluid from the master at each corner when you do a flush. When you see the tiny bubbles in the clear hose. Go to the next corner. My method that we use is what works for us, every single time. Others do it lots of different ways, I’ve tried most of them and I’m not able to make them work as well as a good 2 person manual bleed. They doesn’t mean they don’t work or aren’t successful for others, I just can’t make any of them work every time.

The problem with vacuum bleeders is sealing the straight threads of the bleeder screw at each wheel cylinder. The problem with speed bleeders is you can’t tell if you have a problem because you aren’t able to see the flow and rate at each corner. The problem with pressure bleeders is you can’t always get enough pressure to induce the turbulence needed to get the crap out of the piston bores. The problem with reverse pressure bleeding is you can push the crap that is in the piston bores up into the combo valve and master bore.

Here is ours again-

Cap off of the master and I flip it upside down and lay it back over the opening to slow down a splash that can happen. If the cap isn’t off or loosened, a fast drop in reservoir level can produce a vacuum which makes the bleeding process harder. While the cap is vented, it is a very small vent designed to allow the pressure in the reservoir to equalize to atmospheric without leaking fluid. In case you ever wondered why some of the caps look the way they do.

1718886639660.png

Fluid level full in the master reservoir.

Engine off, key on to power up the dash, parking brake off. You need to know if the brake light is tripping which indicates a shifted shuttle valve.

The valve moves when the pressure is too high on one side. The low pressure side is being closed off or mostly closed off to prevent loss of fluid in the event of a leak. Good safety feature, terrible for brake bleeding. While we do use a lock out tool that replaces the switch in the combo valve to stop the shuttle from moving, we bled 100’s of rigs before that and always managed to get it done easily. In fact, I kinda like not using one because that tells me the system is functioning, the valve will move when needed, and the circuit is good so it will work when it should. Roughly around 03-04, they changed something about the switch. Before then, we never had a single instance of the valve shifting during bleeding. After that, we get some rigs that had to have the dash light reset at every pedal push.

What put us onto looking for a better way or to bleed with the key on was I could hear the valve in the combo block clicking as it shifted.

I use a bottle to collect the fluid and a clear hose on the bleed screw. The hose end in the bottle does not have to be under fluid. That is an old wive’s tale. If you want to verify why, simply open a bleeder and watch what happens. Fluid will run out which means air is not going in and again, we still have the issue of not being able to seal straight threads at the bleed screw so even if the requirement was to have the hose in fluid to stop air from going into the caliper, it would still get in around the threads, it doesn’t. Even if it did, the bleeder is the high point, fluid would push the air up to the bleeder inside the caliper and it would leave at the next bleed cycle exactly as designed.

If you are not having the helper push the pedal down enthusiastically enough that you have to hold the hose on the bleed screw, then they need to do so with some more enthusiasm. A pedal push down should squirt fluid out of the bleeder and across the floor 3-5 feet if you didn’t have the hose in place.

1- you open bleed screw with as wide a swing as possible 2- helper pushes pedal to the floor and holds it at the bottom 3- close bleed screw and tell the helper to let the pedal up.

Repeat 5-7 times per corner.

I start with a gravity bleed. (remember the hose in fluid silliness?) When I have fluid dripping out of the bleeder at each corner, I know I can start the manual bleed. You can also use the gravity bleed to diagnose. If you open the bleeder on a full system and fluid doesn’t come out after enough time that it should have, there is a problem.

The tiny bubbles in the fluid will coalesce after some time. A bleed the next day of 1-2 pumps per corner typically gets rid of them. If you do more pumps, you are putting more bubbles in the fluid. Granted, they will work their way back up into the reservoir or corner eventually but we don’t need that if we don’t have to.

If you have a problem that indicates there is air in the system, stop and find the problem. More bleeding isn’t going to fix it. More bleeding just wastes time and fluid and will not ever solve a problem. Bleeding just gets air out of the system and if the above method doesn’t do that, then the problem will not be fixed, found, or solved by doing more of it.

Last bit of annoyance I deal with frequently has to do with bench bleeding masters. If you could do it in the vehicle, it wouldn’t be called bench bleeding. ;)

doors off mirrors

amazon motorcycle mirrors

jjvw pics in traffic

jjwv install

jjvw product

JMT install

paint match

https://wranglertjforum.com/threads/krew-hangout.18137/post-1616325

I ended up going through www.automotivetouchup.com and bought a few cans of spray paint in the oem Electric Lime Green, scuffed/sanded the corners and rock sliders myself with a DA orbital and sprayed them in the garage, turned out better than I was expecting. Not as “smooth/glossy” as the original paint but a very good color match. I’m sure I could wet sand/clear coat them and they’d get even better.

Still need to pull the front fenders off, scuff them up and then spray with the same paint to get them to match better.