A busy winter, not much Jeep action or news. My father-in-law just bought a 2022 Sahara and is showing interest in some light off-roading. I need to get a few projects completed that I have been putting off for a while now for the spring season.

My Jeep survived its time in the northeast before making it to Texas with relatively minimal rust. One area I noticed early on was the oil pan. There were rust spots that I wasn’t sure exactly how thin the material was and didn’t want to find out. I bought a replacement pan over a year ago and have been waiting for the next oil change to make the swap. That day was today.

The exhaust has to be disconnected at the header and lowered to allow the pan to clear the oil pump pick-up. Having never removed the exhaust before, I had concerns about the exhaust bolts both in being seized and simply accessing the bolt heads for removal. WTJF had the answer, as always. A 15 mm swivel socket, an impact wrench and several extensions made quick work of removing the bolts. I did get the socket hung up once on the inner side of the rear mini-cat but was able to finish it with a ratchet. After that, it was lowering the skid and removing the transmission support bracket to allow the exhaust to droop. I’ll be modifying this bracket to clearance the exhaust around the passenger UCA mount before reinstalling. More on that later.

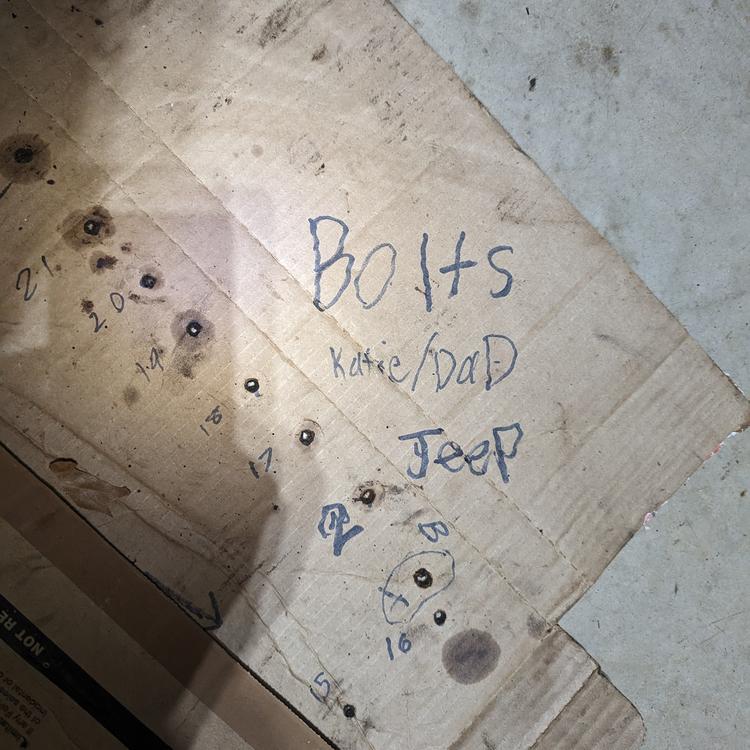

With the exhaust lowered and the starter removed, 26 of the 28 bolts holding the pan were easily removed. the final two at the rear of the block were partially blocked by the oil pan strap(?) (and caked on dirt/oil). Once the socket was on the bolt head, they were also removed.

Removing the old gasket was tricky near the corners where RTV is applied. It took time and patience to get the old RTV removed from the gasket groove. Once everything was cleaned up, reassembly was easy. I used the pins provided with the Felpro gasket. I know a lot of guys prefer to make their own as prescribed by the FSM but these worked well enough. Four corners with RTV and help from my assistant and the new pan was installed.

New pan all ready to go.

All in all not too bad. Glad I researched and planned ahead. I need to correct the exhaust hanger bracket before I can fully reassemble. Spoiler alert: that is done too. The test run went well and as of this morning, no drips. Lots of firsts in this project. Glad to have it out of the way.

While the pan was off, I took a look a the timing chain. I have questions about how much deflection or slack is expected. I’ll do more research on this later, but mine doesn’t look too much different from this example. Here’s a video of the chain slack/deflection in my 4.0L.